Innovating Craftsmanship: Bite Keeper Alarm Set with IP66 Waterproof Rating

In the realm of fishing, reliable bite alarms play a crucial role in ensuring a successful catch. One such groundbreaking product is the BiteKeeper Alarm Set with receiver, which not only delivers exceptional performance but also boasts an impressive IP66 waterproof rating. In this blog post, we will explore the innovative craftsmanship behind this product, starting with the machine dispensing technique, followed by its advantages over traditional manual dispensing methods. We will then discuss the rigorous waterproof pressure testing and its benefits over conventional testing methods.

Craftsmanship Driven by Precision: Machine Dispensing

Traditionally, silicone rings were manually assembled in bite alarms. However, the BiteKeeper carp bite alarms revolutionize this process by implementing advanced machine dispensing techniques. This cutting-edge method utilizes highly precise robotic dispensers to accurately apply adhesive and secure the components. Machine dispensing ensures consistent alignment, adhesive distribution, and bonding strength, surpassing the limitations of manual assembly. By incorporating machine dispensing in alarm ring production, the BiteKeeper bite alarm set with receiver sets new standards for precision-driven craftsmanship.

Advantages Over Traditional Manual Dispensing Methods:

Compared to traditional manual dispensing methods, machine dispensing offers several significant advantages. Firstly, it enhances production efficiency and yield through consistent application of adhesive, reducing variations caused by human error. Secondly, machine dispensing ensures precise alignment and adhesive distribution, resulting in improved product quality and reliability. Additionally, this automated process allows for better control, traceability, and adherence to strict quality standards. These advantages make the Bite Keeper Alarm Set a game-changer in the fishing industry.

Rigorous Waterproof Pressure Testing

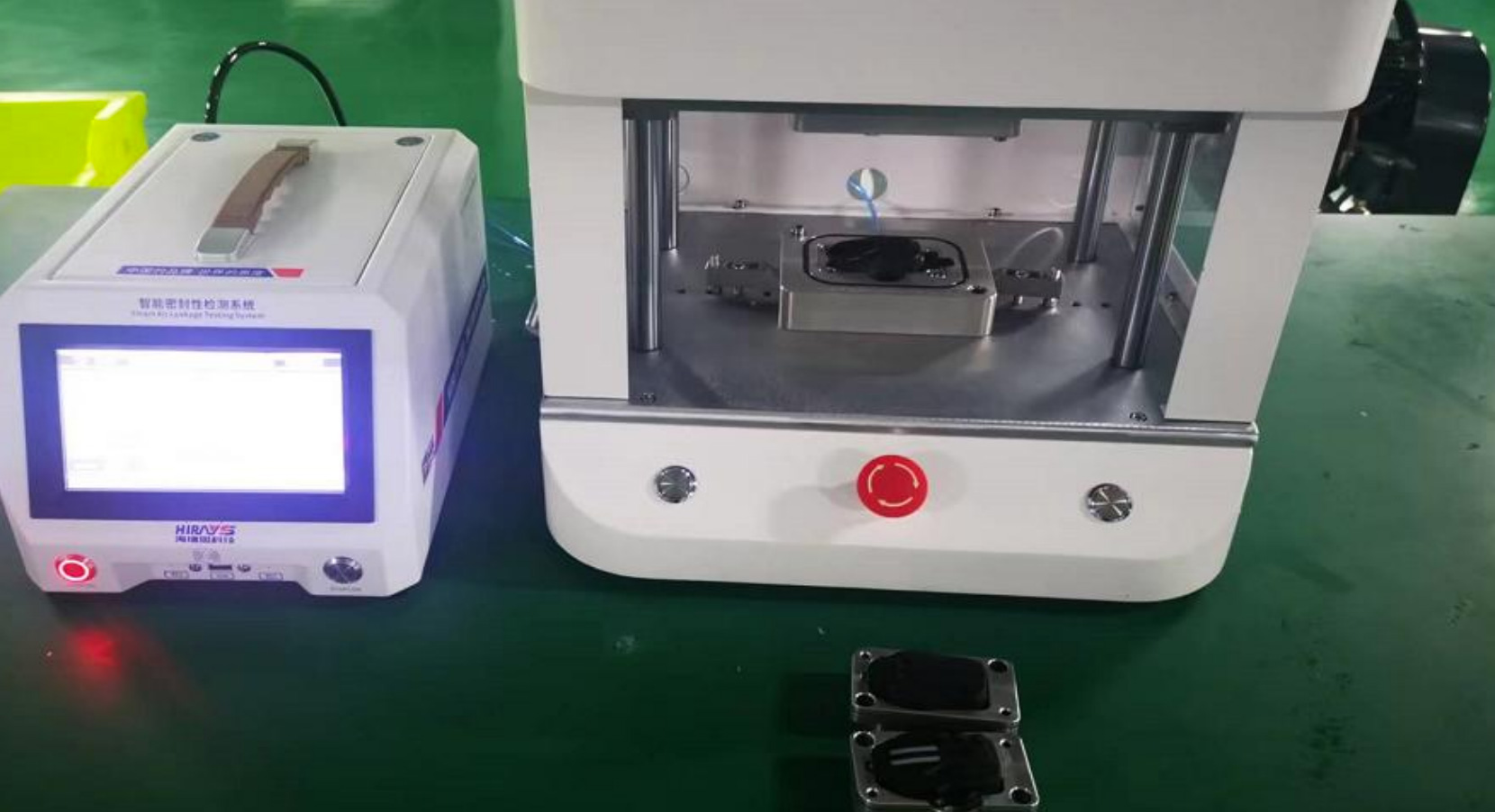

To ensure outstanding performance in various fishing conditions, the BiteKeeper Alarm Set undergoes rigorous waterproof pressure testing. This testing process involves subjecting the alarm units to controlled levels of internal air pressure, simulating real-world scenarios such as heavy rain or accidental submersion. By injecting air pressure, any potential leakage can be promptly identified. This thorough testing guarantees the reliability of the Bite Keeper bite alarms for sale even in the harshest weather conditions.

Advantages Over Traditional Testing Methods

Traditional testing methods relied on manual examination by submerging fully sealed alarm units and observing air bubbles for leaks. However, the BiteKeeper bite alarm set with receiver introduces a superior alternative: pressurized waterproof testing. This method offers several advantages over traditional approaches. Firstly, it provides a more controlled and quantifiable assessment of waterproof capabilities by measuring the air pressure required to cause leakage. Secondly, pressurized testing reduces the potential for human error, ensuring consistent and reliable results. Finally, it allows for better traceability and record-keeping, aligning with stringent quality control processes.

The BiteKeeperbite alarm set with receiver excels in craftsmanship innovation, featuring machine dispensing techniques for precise assembly and a robust IP66 waterproof rating. By implementing advanced manufacturing processes, such as machine dispensing, this product guarantees exceptional performance and reliability. Furthermore, the rigorous waterproof pressure testing ensures that anglers can rely on the BiteKeeper carp bite alarms even in the most challenging fishing environments. With its superior craftsmanship, durability, and IP66 waterproof rating, this innovative bite alarm set sets new standards for excellence in the industry